| Home > RX-7 > Tech/Mods > Modifications > Porting The 4 Port Turbo II Lower Intake To Fit The 6 Port NA Block |

| Home > RX-7 > Tech/Mods > Modifications > Porting The 4 Port Turbo II Lower Intake To Fit The 6 Port NA Block |

If you want to turbocharge your 6 port NA 13B, the easiest way to accomplish this is to port match the TII lower intake manifold to fit the engine. From there, all the other TII parts will bolt to the block and you have what I like to refer to as a "6 port TII". Note that this is distinctly different then what I refer to as a "turbo-NA" setup, as the turbo-NA setup is about using most of the NA engine and fabricating parts to turbocharge it, while the 6 port TII setup basically involves bolting all the TII parts onto a 6 port block.

Once the TII LIM is port matched to the 6 port block, it bolts right on in place of the NA LIM. The stock TII exhaust manifold and turbo will now bolt on as if the block is a factory 4 port TII block, as well as any aftermarket turbo and manifold made to upgrade a TII. The TII upper intake is used and then all that is necessary to finish the job is to take care of coolant oil to the turbo, and of course the appropriate fuel system.

Covering the entire 6 port TII upgrade process is not what this article is about, so the rest of that is up to you. Once the TII lower intake is installed on the 6 port block, it is outwardly equivalent to the "real" 4 port TII engine so you can proceed with the rest of the installation following standard TII swap writeups. Rotary Resurrection provides a good overview of the TII swap process, and the process is well documented on the RX-7 Forum. Additionally, there is a thread on the TeamFC3S forum which covers a members 6 port TII conversion using this method of intake manifold modification. Another good resource is my The (Almost) Complete Guide To Turbocharging The Naturally Aspirated Second Generation RX-7. While that guide refers to making a turbo NA using fabrication, it has some helpful info on some things you will need if you are doing a 6 port TII setup: turbo oiling system and many other oil/water supply options. Finally, the following updates to my Project Tina include information about supplying oil and water to the turbo on an NA block: May 13, 2002, June 9th, 2002 (primarily page 2), Aug. 7th, 2006, July 18th, 2007 (page 2 and 3).

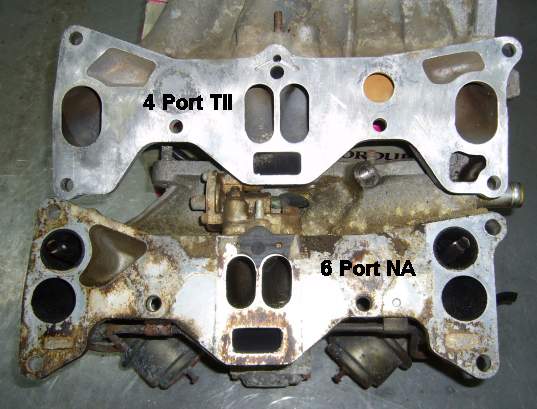

Now with all that out of the way, let's get to the point of this article. The image below shows the difference between the 4 port TII lower intake on the top, and the 6 port NA lower intake (in this case, from a GSL-SE 1st gen) on the bottom. While the ports appear to be in different locations, they actually "almost" line up. As well, all of the bolt holes are shared between both manifolds, so the 6 port manifold will bolt to the 4 port engine and vice versa.

The idea is to make the secondary (end) ports on the TII lower look like the secondary and aux ports on the NA lower intake. To do this, the two cavities above the secondary ports on the TII lower intake will be filled with epoxy and then that area will be ground out to match the pattern of a 6 port NA lower intake manifold gasket.

Once the grinding is finished, clean the entire manifold flange, cavities and runners with a residue free solvent such as brake cleaner. Thoroughly dry the area, preferably with an air compressor.

It will take about a day for the epoxy to cure fully, or even longer if the temperature is low. Give it a few days just to make sure because the whole project will become a huge mess if you start grinding and hit a pocket of uncured epoxy.

Once the epoxy is fully dry, take out your sanding block and knock down most of the excess epoxy that might be higher then the flange. You don't need to make it perfectly flat, we will do that later.

When the tape and gasket is removed, your manifold should have the area to be ground out clearly marked on the 4 port manifold.

When starting the port, just concentrate on removing much of the material that is in the way. Rough out the port shape while moving a bit up and to the left, following the runner. There is actually quite a lot of material that can be removed from the left port wall to tie your new port into the runner. But don't go hog wild on the right wall as there is a thin casting there to make room for the bolt which secures the flange to the engine.

Once you have the basic port shape established, you can refine it. The left side of the port can be ground so that its wall matches up with the wall of the manifold runner. However the right side needs to taper out from the wall of the runner to avoid grinding through the casting around the bolt hole. The top of the port can be a very slight taper from the manifold runner outward. While you are porting, check the wall thickness between your fingers to make sure you aren't in the danger zone as every casting is a little different. There is quite a lot of material to remove where the manifold runner will meet your port. Spend a good amount of time smoothing that transition and make sure you are not creating any sharp lips where the runner meets the port.

You can see from the pictures above how the walls on the left side of the port taper into the runner, while the walls on the right side of the port taper out from the runner. A good amount of time has been spent inside the runner where the camera cannot see to match the runner to the new port.

The last picture shows how you can go heavily into the runner. This is important for airflow. It is also very important that you keep the size of the ports the same on both sides of the runner. If there is a significant difference between the port sizes, airflow will not be the same through each one and you will end up with an uneven air/fuel ratio between the rotors.

Back To Mods Page | Mail Me | Search | ![]()