| Home > RX-7 > My RX-7 > Project Tina > Project Tina, October 1, 2005: Engine Installation, POR-15 Undercoating, ECU Wiring and Battery Box Fabrication |

| Home > RX-7 > My RX-7 > Project Tina > Project Tina, October 1, 2005: Engine Installation, POR-15 Undercoating, ECU Wiring and Battery Box Fabrication |

Its that time again. Yes, time for another installment of my ongoing turbo-NA-bridgeport project. As always, things have been progressing. Sometimes slowly, sometimes quickly. Quite a bit of work has been done since the last update. Without further rambling, let's just get to the interesting stuff.

When we last left off, my intake and throttle body flanges had just come back from being made. The machine shop cut them on a water jet machine from the CAD drawings I sent it. I will be certainly using the intake flange, but the throttle body flanges will not be used. There's nothing wrong with them, I just have no need...but details on that will come later.

It's time to prepare to reinstall the engine. First steps are to install the lower intake, water pump housing, and water pump. Nothing special here. New gaskets were used, as well as all stainless hardware. Notice that the water pump housing has NOT been tapped for an aftermarket temp gauge. At that point, I had not decided which gauge to use. The decision has since been made, so it will be a bit of a pain to drill and tap while on the car. At least the cast aluminum is soft.

After the water pump was mounted, the eccentric and water pump pulleys were installed. These are rotating parts, so blue Loctite was used on all (stainless steel) bolts.

Now time for the turbo manifold. Anti-seize was applied to the threads, then the exhaust spacer and manifold were bolted in place. As I have mentioned before, the stock turbo is only being used for breakin, so the stock turbo components have not been cleaned up and painted.

It was then time to bolt on the turbocharger. Notice the copper locknuts. A major problem with most TIIs is that the turbo nuts loosen up over time. From the factory, they're fine. But once removed and reinstalled, they always seem to loosen again. These copper nuts are available from ATP Turbo for about $1 each. Being made of soft copper they really grip the stud. There is also a locking ring above the main threaded portion. Once tightened they WILL NOT LOOSEN up without great effort. One thing to keep in mind if you use these is that when torquing them down, the nuts must be gripped on all sides. If you use an open ended wrench they will simply round off.

Once the turbo was solidly mounted the controversial oil drain hose was installed. However, it would not remain attached for very long.

Finally, the flywheel was mounted. The oil seal was coated with assembly lube, the flywheel key inserted, and then the flywheel itself slipped over the shaft. When torquing the nut, the "crude" method was used. It was snugged up by hand, then banged on with the impact gun until it wouldn't turn any more. At this point I was going to install the clutch, but found that the flywheel had damaged threads due to...um....me trying to hammer one of the dowels into the wrong hole. As I didn't have the correct tap for the threads, the clutch would have to be installed later.

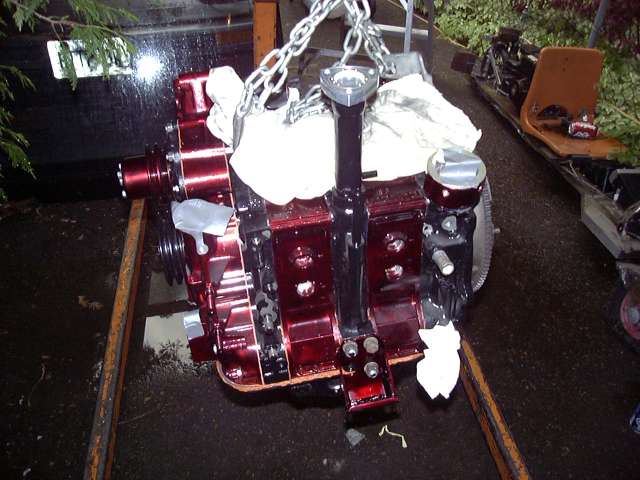

Almost time. The engine was hung from the hoist in preparation for installation. Until now you may not have noticed that it was raining that day. Actually, it was pouring. Earlier in the day I had to erect a temporary shelter at the mouth of the garage to keep out the weather. In general things were kept fairly dry but once and a while the wind would blow some moisture underneath the tarp.

And the engine is being lowered in place.

Well there you have it. For the first time in nearly 3 years, the car and engine are once again together. Aside from some frustration with the passenger side engine mount nuts, the process went very smoothly. Note the twine used to prevent the engine from falling backwards. As of yet, no transmission had been mounted to support the rear end.

The radiator was then mounted. New rubber bushings were previously ordered from Mazda and of course stainless bolts with plenty of antiseize were used.

Yes, I run an electric fan. The reason is simply because my clutch fan failed several years ago, and I didn't feel like paying the high cost for replacement. This fan was originally on a Pontiac 6000 but they can be found on many GMs up to about the mid to late '90s. These fans fit the stock rad almost perfectly and have a decent shroud. Even though they seem poorly made, they are quite reliable and a dime a dozen to buy. I disassembled this fan, cleaned everything up, painted the motor black and painted the shroud with MetalCast plastic primer followed by 4 layers of MetalCast red. The brackets were made by simply welding two pieces of 3" steel together and then drilling the appropriate holes. As you can see, they fit the stock shroud mounting locations.

This next picture doesn't seem like much, but it represents a little more then 4 weeks of work. It may also seem unnecessary and odd to those in climates that do not experience snow, so I will explain a little. Along with the previous owners of my car, I am guilty of driving it in the winter, though I have not done so since 2001 and do not plan to ever again. This would not be so much of a problem save for the fact that to melt the ice and snow, copious amounts of salt are spread on the roads. As you may have guessed, salt + moisture + steel = rust. In fact, Southwestern Ontario is known throughout most of Canada as "the rust belt". I'm not saying that my car is rotted, or that it's falling apart at it's seams, but as with many 20 year old cars that were winter driven it did show a few areas of concern. I made the decision that if I was going to clean up the underside, I would do it once, do it right, and be done with it. For years, on many of the automotive lists that I read, I have been hearing about the virtues of POR-15 Rust Preventative Paint. Many of the most anal, fickle and obsessed enthusiasts I have ever seen have literally entrusted their most important posession to POR-15. It is one of the few products that I have never heard anything negative about. Because I wanted permanent protection, and was only planning to do this job once, I ordered a gallon can of POR-15, and a gallon of their MetalReady pre-primer.

Let me just say one thing first: This was the worst job I have ever done, and I am an idiot for doing it. On a hot July Sunday, I put the car up on ramps and began preparing the underside for painting. Now, POR-15 does not require a completely stripped surface, and indeed it prefers to bite into rust rather then shiney clean metal. Knowing this, I began stripping the underside of all loose rust flakes, factory undercoating, and the 1/8" coat of dirt and oil that had accumulated over the past 20 years. This entire process took one month of working several hours a day (and 8 hours a day on weekends) to complete. Rust was removed with a wire wheel, wire brush and pocket knife. On a tip from Jeff, I used kerosene to quickly strip the factory undercoating. Everyday, this job left me absolutely filthey. My skin went from pale white to black/rust everytime. It took three attempts to totally clean my hair, and I just started not even bothering to try and wash the clothes. Finally, after 3 weeks of torture, it was basically over. The underside was then degreased and washed until it was SPOTLESS, which took several attempts.

Before POR-15 is applied to a surface, that surface must be etched with a product called MetalReady to prepare it. The metal ready neutralizes existing rust, etches bare metal, and leaves a zinc coating for the POR-15 to adhere to. MetalReady is applied, allowed to sit for 20 minutes or so, then rinsed off. What the instructions don't tell you is that MetalReady's main component is phosphoric acid. So in the process of crawling under the car and thoroughly soaking it with MetalReady, I also thoroughly soaked myself with phosphoric acid. This left me with acid burns over most of my body that took about a week to heal. Aside from the searing pain, half of my face looked like The Phantom Of The Opera, so I had to constantly endure the question "What happened to your face?". To the credit of who wrote the instructions, they do tell the user to wear gloves, which I did.

After another week of drying, it was finally time to apply the actual POR-15. On a humid Sunday morning, I began the process. The first coat took several hours to apply, and by the time I was finished I had to immediately start the 2nd coat. I'm not sure that anyone can appreciate how much of a royal pain in the ass painting overhead in a cramped space is. For 6 hours, I contorted my body, slid around on my back, put up with paint drips on my face and sweated my butt off. Finally finishing around 4:30PM, I was literally COVERED HEAD TO TOE in POR-15. Now, the instructions mention that if you get the paint on your skin, nothing will take it off. You better believe they're right. As I was covered in huge amounts of paint, all I could was let it wear off, which took 3 weeks. Imagine that someone had dumped a gallon of black paint on my head, then tripple the amount of paint you are picturing to get an idea of what I looked like.

Would I do it again? Absolutely not. I would rather put a red hot corkscrew in my rectum, twist it slowly and sing hit singles by Britney Spears. But am I happy with the result? Yes, and confident that the hard, slick surface of POR-15 will protect the car for many years.

The white areas of the picture below are actually reflections from the camera flash, not flaws in the paint.

Once the underside had cured for a week, it was time to reinstall the transmission. Work doesn't stop just because 85% of your body is sealed in POR-15, you know.

One of the things that had always annoyed me about the car was how mushy and loose the transmission mounts were. This caused the shifter to bounce up and down over bumps and rough roads. The solution is shown here in the form of a brand new transmission crossmember (with lower bushing) and new "competition" side mounts. The second half of my mush-elimination plan is custom shifter that totally eliminates the FC's bushings, but that's another post for another day.

Before the transmission was installed, the clutch of course must be mounted. I quickly used a tap to clean up the flywheel threads, degreased the flywheel surface with brake cleaner, then installed the disc and pressure plate. An alignment tool makes this very easy, but in a pinch a screwdriver can be used. To prevent damage to my new pilot bearing and seal during transmission installation, I made sure that alignment was perfect with the proper tool.

I could swear that I took a picture of the new throughout bearing that I used, but you'll just have to trust me that it's there.

The transmission slid into place fairly easily after some wiggling. The electrical connections were made, and then the starter bolted into place. I clearly cheated and painted only the bellhousing of the transmission. No one in their right mind paints the whole transmission, right? That big scar of scrapped paint on the left of the transmission tunnel was caused during installation. The only reason the POR-15 flaked off was because it was an unprepared area where the underlying paint was already weak. Properly applied POR-15 is as hard as powder coat.

Shown here is the single most expensive part on the entire engine. Well, not really. But if you have to buy one, you will certainly start to think so. This is a brand new primary injector air bleed. I had to lay out $45 for this thing because the original broke during removal.

The new primary injector bleed was installed, and new o-rings installed on the remaining old bleed. After that, I began installing some of the other engine components. The CAS, thermostat and water neck, oil fittings, primary injectors and fuel rail and finally the clutch slave cylinder are shown here.

A wider shot, now showing the ignition coils, charcoal canister, wiper motor and fuse panel. The ignition coils were previously disassembled and painted, as was the wiper motor and charcoal canister. Some may wonder why I am keeping the canister. The reason is quite simple actually; I don't want my car to stink like fuel, and there's no good reason not to use it. The original plan was to just paint it black, but I decided to make a statement so it was primed, then sprayed with sliver metal flake, then finally coated with 5 layers of MetalCast red. I will be running stock purge valve to vent both the canister and crankcase. Most of the wiring to the fuse box has been greatly simplified so it fits in a small single harness. The 12V supply wire will eventually come from the passthroughs on the firewall.

Another rather poor image of the engine bay showing the primary injectors and turbo oil drain.

These are the metric to -10 AN fittings for making custom oil cooler lines. New crush washers were used during installation, as well as Teflon sealing compound on the threads. The small 90 degree fitting is a 1/4" elbow for oil supply to the turbo. The appropriate NPT to AN adapter will be added when the time comes.