| Author |

Topic Topic  |

|

urquiola

Apprentice

Spain

97 Posts |

Posted - May 20 2010 : 11:26:20 AM Posted - May 20 2010 : 11:26:20 AM

|

Hi!: as you all know, when Toyota presented the concept of air injection in exhaust port to improve Wankel performance, specially fuel economy, they added also a Reed Valve (RV) close to the trochoid surface in the peripheral intake port; peripheral intake with variable geometry intake manifold made Mazda win Le Mans endurance and fuel use race (-SAE Paper 920309 , Ritsuharu Shimizu et al.). Yanmar Diesel showed also that reed valves improved the partial load and low r.p.m. performance of their small charge-cooled rotaries (SAE Paper 720466 Kojiro Yamaoka & H. Tado), but I got a letter from David W. Garside, that developed the Norton series of Rotary engines, telling that reed valves do impair the high r.p.m. performance, an untoward fact for their engines. As street car engines don't work long times at high r.p.m., anything improving low rpm and partial load performance would be very good for the average driver. RVs do generate opening and closing extra-flows, like an hydraulic ram, that improve volumetric efficiency; also, by tilting the RV angle, you can induce any desired amount and direction of swirl inside the combustion chamber, thus regulating flame speed and engine emissions. I had the concept of installing an Husqvarna 500 cc 2-Stroke engine prismatic reed valve in a rotary with peripheral intake, to improve low speed torque, fuel economy and emissions. I send this note to see if there is anybody with the expertise and will to receive the torch of this concept, implement it and let us know the results. Regards, salud +

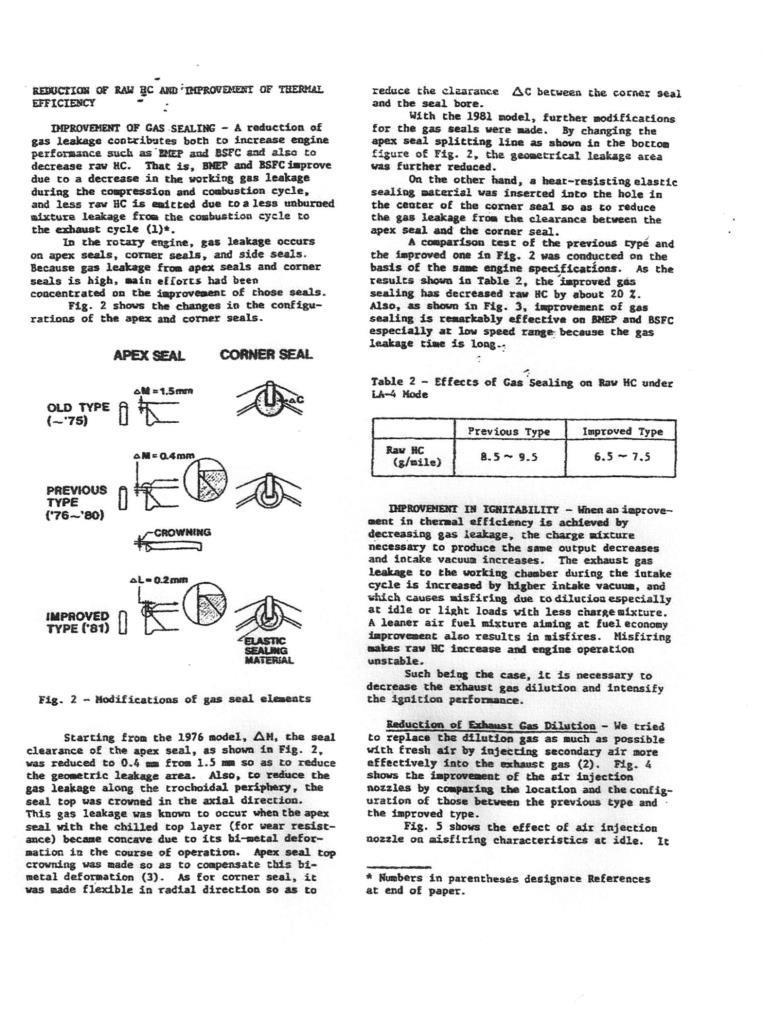

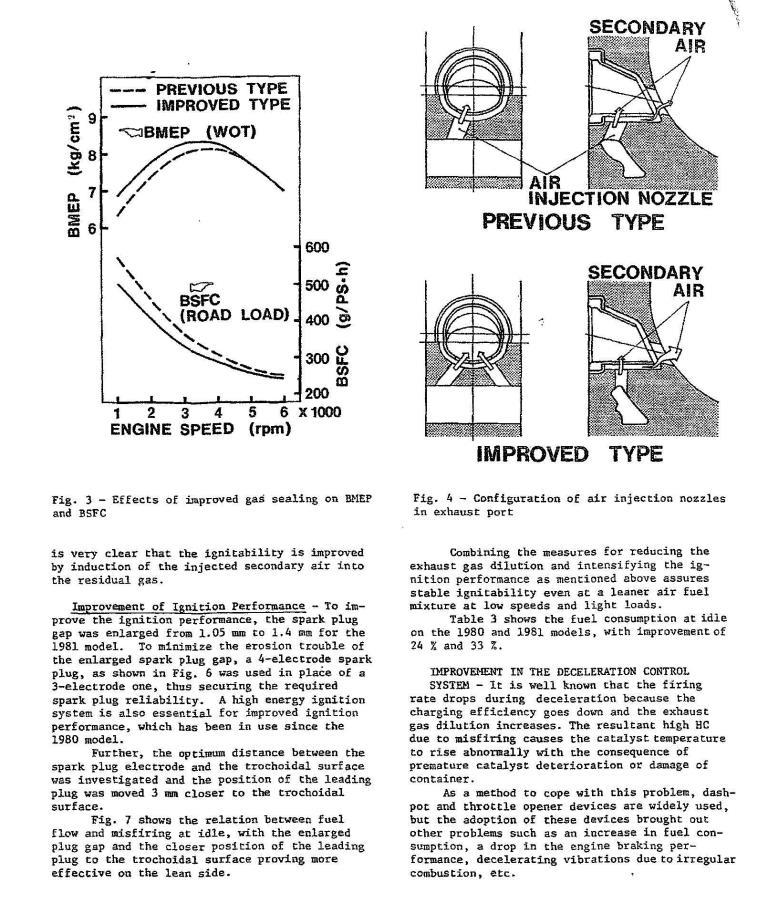

The added images are from Mazda SAE paper 810277, about their improvemnts in materials and engine noise reductions

Download Attachment:  Mazda 810277 a.jpg Mazda 810277 a.jpg

144.65 KB

Download Attachment:  Mazda 810277 b.jpg Mazda 810277 b.jpg

155.41 KB

|

Edited by - urquiola on Jan 14 2016 12:06:15 PM |

|

|

Aaron Cake

Administrator

Canada

6718 Posts |

Posted - May 22 2010 : 11:09:58 AM Posted - May 22 2010 : 11:09:58 AM

|

| Exhaust overlap is the issue. Unless the reed was flush to the housing surface so that there was no leakage around it, then exhaust would still blow past and contaminate the intake charge. |

|

|

|

urquiola

Apprentice

Spain

97 Posts |

Posted - May 22 2010 : 3:56:26 PM Posted - May 22 2010 : 3:56:26 PM

|

| You're right, but exhaust gas entry into the admission stroke has been an inherent feature of Wankel until Renesis engine, and many reciprocating 4-stroke engines used Exhaust Gas Recirculation (EGR) to reduce NOx emissions (For example, the 1976 AMC Pacer I own). H Ricardo showed in the 20's that for every 1% of EGR in the intake mix, you get a 45ļ F reduction in flame temperature, and the higher the combustion temperature is, the higher the amount of NOx in exhaust is. The SAE paper by Toyota (Toshiyuki Kohno, # 790435) contains detailed calculated and measured data on a reed-valve controlled intake engine, including intake-exhaust overlap, dead space next to the intake port and Reed-Valve, and EGR.(See also SAE Paper 921444 , by Marcos Langeani, on a Wankel RCE with High Pressure Recirculation of Unburned Gases). Also, a Reed valve controlled intake port may act as a variable timing intake, always opening and closing to give the better chamber filling and volumetric efficiency. As in other engines, it's hard in a Wankel conciliating the arrangements for low speed torque and fuel economy, and a high power output with the engine raced. A Reed valve would help in having more achievements in both the bottom and high end of engine rpm range, the losses at top rpm would be negligible for automobile use, a family car or common car is not a racing motorcycle or a snowmobile. Anyway, thanks a lot for your interest, any experimental data wellcomed! Salud + |

Edited by - urquiola on Jul 04 2012 8:12:54 PM |

|

|

|

urquiola

Apprentice

Spain

97 Posts |

Posted - May 23 2010 : 11:42:56 AM Posted - May 23 2010 : 11:42:56 AM

|

I've read your personal page. May I advise you "Forbidden planet" a B series sci-fi movie from the the 50's, a cult one, and also "Liquid Sky", by Slava Tsukermann? Enjoy them. SAE papers as you know can be bought at www.sae.org for prices starting around 18 USD, no need to be a member. For a single peripheral intake port Wankel, I guess a nearly rectangular shape port will fit best, as in the Norton series of engines. I've always considered if streamlining the intersection of intake and exhaust ducts with trochoid surface will give an improvement. Streamlining port edges by grinding reduces or eliminates transition from laminar to turbulent flow, a thing linked to an increase in working fluid drag and decreased volumetric efficiency, but in the point where flow detachs from surface, stops being laminar to become turbulent, an important raise in gas pressure occurs, high pressure that sometimes can be exploited to give beneficial effects, but turbulent flow always reduce volumetric efficiency. See motor rotativo espaŮol in YouTube http://youtu.be/ziM7Cfv_wYU for another unusual engine, some additional info is in www.enginehistory.org . Salut +

Download Attachment:  Duct shape and efficiency.jpg Duct shape and efficiency.jpg

49.6†KB |

Edited by - urquiola on Jan 01 2013 3:44:14 PM |

|

|

|

Aaron Cake

Administrator

Canada

6718 Posts |

Posted - May 24 2010 : 09:48:21 AM Posted - May 24 2010 : 09:48:21 AM

|

Yes, but peripheral porting increaes overlap significantly. Regardless of whether the runner itself is sealed, there is a large hole in the side of the rotor housing that leads directly from the exhaust side of the rotor to the intake side. Unless the valve closes flush to the housing surface, the high pressure exhaust side will always force gas into the low pressure intake side. A flush closing valve has other issues, such as maintaining tolerances, speed of actuation and carbon buildup.

Most of Mazda's factory PP engines did indeed have a square or D shaped peripheral port shape so that they could control the opening and closing speed of the port. |

|

|

|

urquiola

Apprentice

Spain

97 Posts |

Posted - May 24 2010 : 4:50:39 PM Posted - May 24 2010 : 4:50:39 PM

|

| Some if not most of EGR in peripheral porting comes from low intake pressures during part load or low rpm functioning, the exhaust gas pressure being higher, burned gas goes up the intake ducts, charge is poor, and misfirings can also result. A reed valve prevents most of this, while there is always some dead space thru which EGR can happen, the Toyota paper quantifies it. Yes, overlapping may be a disadvantage, but probably the overall result will be good, as Peripheral Porting produces much higher Mean Effective Pressure (MEP), and higher MEP gives better Specific Fuel Consumption (SFC) (SAE Paper 680572, H Keller). I guess that in some Peripheral Ported (PP) engines, a more than noticeable flow of exhaust gas reached the intake manifold and continued its way up in the actual working conditions. The issue is that Mazda won the Le Mans race with peripheral ports, and for me a single R-V controlled PP would be worth testing in a car engine, maybe just small additional peripheral porting for idle, as in Suzuki RE-5 would be of help (SAE Paper 770190; Shigeyasu Kamiya et S. Shirasagi) The Norton rotaries (SAE Paper 821068; D W Garside) as well as the Suzuki RE-5 used a gas throttle very close to the trochoid surface (Throttles are usually placed in the carburetor itself, you know this), thus throttle acted in fact in these PP RCEs (Rotary Combustion Engines) as a R-V or a non-return valve would, mainly under not full-throttle operation. What about peripheral intake port (An R-V controlled port would go better) plus side exhaust ports?. I don't know if this has ever been tested, but sounds good. Some of the early Wankel engines of NSU had side intake and side exhaust ports, as in the Rx 8 Renesis engine, but they tended to have problems of carbon accumulation and thermal distortions. Mazda solved the carbon deposits buildup by adding an scraper seal in the sides of rotor, and the rest by adding ceramic parts and other changes I'm not aware of. Do you have experiences you want to share about duct and port streamlining or polishing? Thanks, Salut + |

Edited by - urquiola on Jul 14 2012 11:01:47 AM |

|

|

|

Aaron Cake

Administrator

Canada

6718 Posts |

Posted - May 30 2010 : 10:36:52 AM Posted - May 30 2010 : 10:36:52 AM

|

Then test it.

And you'll find that unless you can seal the peripheral port flush with the rotor housing surface, the overlap will be significant. |

|

|

|

urquiola

Apprentice

Spain

97 Posts |

Posted - Jun 02 2010 : 1:06:58 PM Posted - Jun 02 2010 : 1:06:58 PM

|

| That's the reason why I wrote in the forum, I have no mechanical expertise, repairshop or machining facilities to do it by myself, and third party work costs are well above my reach, so I try to convince others to do the job and let all of us know the results. With the exception of Renesis engines (See SAE Paper 2004-01-1790, Masaki Ohkubo et al.), there was always some overlap between intake and exhaust strokes and ports in rotaries, but overlap is a deliberately wanted feature of high speed reciprocating engines, to improve volumetric efficiency at high r.p.m. A lot of overlap is harmful, but some can be tolerable. I've realized in your YouTube video on restoring a Cosmo Rx-5 that you're already implementing duct and port streamlining, so the idea was not bad. There are also several alternatives to all-liquid cooling.( SAE Paper 900035, D Eiermann et al.) If somebody accepts my request, please let us know. Regards, salud + |

Edited by - urquiola on Jan 01 2013 3:45:50 PM |

|

|

|

urquiola

Apprentice

Spain

97 Posts |

Posted - Jun 03 2010 : 09:49:52 AM Posted - Jun 03 2010 : 09:49:52 AM

|

| Hello again! (A nice videoclip by Andy Warhol on "The Cars" song): peripheral porting always involve some geometrical intake and exhaust ports and timing overlap, but the functional or breathing overlap caused by this is reduced, if not eliminated in its negative consequences, by the decrease in dead space and non-return flow control implemented by the reed-valve. Flow of unburnt gas from intake port to exhaust because of port overlap is one of the reasons of high fuel use, high unburned hydrocarbon emissions and high exhaust temperatures under some rpm and load conditions in Wankel engines, (SAE Paper 890212 , C Kappos & S Rajan and 880628 by T Chen) but reed-valving may help in correcting this too. Early 20th century reciprocating engines had high exhaust temperatures, a consequence among other things of the very low compression ratio the existing gasolines allowed, it was not until the work by Harry Ricardo that the reasons for detonation were discovered, and ways to control it were developed, such as the now defunkt leaded gasoline. Please try R-Vs! |

Edited by - urquiola on Jan 01 2013 3:39:06 PM |

|

|

|

urquiola

Apprentice

Spain

97 Posts |

Posted - Jun 04 2010 : 10:48:12 AM Posted - Jun 04 2010 : 10:48:12 AM

|

| I forgot to say, that a way to avoid the negative consequences of port overlapping, while preserving the MEP and other performance advantages of peripheral porting, is having a peripheral, reed-valve controlled, rectangular intake port, and side exhaust ports, as in the exhaust ports of Renesis engine. Side exhaust porting was used early in Wankel development, but the build-up of carbon deposits and other problems (Thermal distorsion,...), solved in the RX-8 engine by new side seals, impeded its generalization. By the way: I remember reading in a rotary engine company webpage, BDC motorsports I guess, interest on the Nickasil coverage for trochoid surface. This coverage was invented elsewhere, and the resulting surface had some kind of roughness as to retain the lubrication oil film, and also low wear and good compatibility with apex seals of an adequate long duration. The patents by CitroŽn (or Rolls-Royce, or Mercedes ?) can be downloaded for free from several patent offices around the world, as they have expired; it just takes some time to find the right patent among all patents owned by Automobiles Andre CitroŽn (Try friction or rub surface as search word, or www.oepm.es pats # 0374366 and 0375053 , or the worldwide patent database ESPACENET), and also the canadian patents from Grazen, Alfred P, describing the housing working surface layer used in the Suzuki RE-5 (CA 602098 and CA 651826), that allowed employing new Ferrotic alloy apex seals (SAE Paper 741043 H D Lamping et al), and gave an engine life of more than 250000 km, are of free download. There is an spanish motorcycle company, Derbi, several times World Champion in small engines bykes, now owned by an italian firma, that was applying Nikasil, I don't know if they do it currently, in their reciprocating engines cylinder inner coating, it can't be difficult to contact them, many people can help you as translators if you're in trouble. Some new developments for cylinder wall treatment, easier to apply and cheaper than the ones used in the OMC engines (SAE Paper 730119 H M Ward, III et al.; SAE Paper 740147 , V Meringolo & F N Longo) for example, that in theory can be useful for rotaries, were recently published in SAE papers (2008-01-1050: K.Bobzin et al, Germany: Thermal Spraying of Nano-Crystalline Coatings for Al-Cylinder Bores). The Nikasil coating was developed, I'm not sure, by Rolls-Royce or Mercedes-Benz, and the good feature in this product is that it gives a strong, durable sliding path for the apex seals, and as it's somehow porous or not fully flat, it allows the lubricating oil film to stay and keep the engine away from becoming stuck or wearing too fast. A suggestion: never,never race a Rotary engine under no-load conditions: it can simply blow away. Enjoy it all. Salud + |

Edited by - urquiola on May 05 2012 10:11:44 PM |

|

|

|

Aaron Cake

Administrator

Canada

6718 Posts |

Posted - Jun 06 2010 : 10:40:15 AM Posted - Jun 06 2010 : 10:40:15 AM

|

In all honesty, I'm not going to try it. I'm not willing to spend money on machining costs and a month or so of R&D on something that I know won't work. I also don't really see the advantages. I can take a zero overlap side-port rotary, strap a turbo onto it, and make more power then a peripheral ported rotary anyway.

I still don't see how a reed valve would stop or even limit exhaust overlap. A reed valve must open towards the flow, so there would still need to be a huge dead space through which high pressure exhaust will force its way into the intake charge. There won't be a functional difference between an engine without a reed valve. This has been tried before. |

|

|

|

urquiola

Apprentice

Spain

97 Posts |

Posted - Jun 06 2010 : 2:37:10 PM Posted - Jun 06 2010 : 2:37:10 PM

|

| Peripheral porting gives a much more higher mean effective pressure than side porting, and a high MEP is one of the good features for high output and good fuel economy; the main advantage for side intake porting is a more stable idling and some better part load and low rpm performance, plus the avoidance of bad overlap, there is no problem for overlap, just the EGR and unburnt mixture scape thru exhaust port are the problems, but this is also the advantage of reed-valving: you keep the better MEP throughout the whole rpm span, and regain most if not all of the side port non-overlap and part load features. Also the opening and closing of valve may generate extra flows, a thing used with liquids for what is called hydraulic ram. As many of the peripheral intake porting problems are connected to the reverse flow of gases to intake manifold, and short-circuiting of unburnt air-fuel mixture to exhaust port, the combination of a peripheral, reed-valve controlled intake port, and simultaneously a side exhaust port,would have both the high MEP of peripheral porting and the absence of or minimal overlap of side intake and side exhaust porting of the Renesis engines. The question of turbo-charging is addressed at SAE Paper 900036, by I Matsuda et al. as you know. (Data on exhaust gases behaviour appear in SAE Paper 930681, Y Hamai & E Outa ). As I've tryed for years to involve somebody in this project, with no success at all, I'm not surprised that you all don't like wasting your time, money and expertise on such an apparently foolish idea. Anyway, I'm very grateful to you for giving me the opportunity to spread the concept. Should you ever change your mind, please let me know, you can look for me here, and searching for jgrosay, the nickname I use in Wikipedia , NY Times, Amazon, and SciAm. Nice summer, take care of mosquitos!. Salut + |

Edited by - urquiola on Mar 24 2012 9:57:30 PM |

|

|

|

Aaron Cake

Administrator

Canada

6718 Posts |

Posted - Jun 07 2010 : 09:44:52 AM Posted - Jun 07 2010 : 09:44:52 AM

|

I never said the idea was foolish, just that it wouldn't work.  Very rarely do I say that an idea is foolish. Very rarely do I say that an idea is foolish.

Here is a diagram that I created to explain the issue of overlap. It sucks, but I did it in about 5 minutes in MS Paint. I have an engine simulator application that allows me to run a rotary at any RPM and position to determine timings. Note that I just guessed on the location of the ports to illustrate the point, don't take this diagram as actual peripheral port timing.

As you can see, even with a (poorly drawn) reed valve, there is still ample space for the port to allow exhaust gasses through. By the nature of the reed valve, it needs to be a certain distance from the port so that it has room to open. Unless some kind of electrically/hydraulically actuated reed valve is used that can open the opposite way, but that seems unlikely. Exhaust gas pressures in this area aren't trivial, they are many times higher then intake pressures.

Rotary and "fuel economy" really don't belong together. It is very hard to get decent fuel economy, not due to porting, but due to the long and weirdly shaped combustion chamber. |

|

|

|

boron

Mad Scientist

Canada

223 Posts |

Posted - Jun 07 2010 : 5:21:05 PM Posted - Jun 07 2010 : 5:21:05 PM

|

| Man I love MS Paint. It's not really that bad a drawing btw. |

|

|

|

urquiola

Apprentice

Spain

97 Posts |

Posted - Jun 07 2010 : 5:47:46 PM Posted - Jun 07 2010 : 5:47:46 PM

|

You may be right, I may be crazy (1), but: what about my last proposal, a peripheral intake port and side exhaust ports?. Most early Mazda engines had side intake and peripheral exhaust, the overlap was minimal. It's just putting the type of ports upside down, boy you turn it...(2). C Jones in SAE paper 770044 tells about having made an engine turn backwards to test the peripheral intake with side exhaust configuration, but this concept, and the concept of putting intake and exhaust zones upside down involves the risk that, as the flow of cooling fluid is set for a precise location and amount of heat transferred from the rotor chamber to the housing and then to the cooling system, having thermal distorsions that will give poor emissions and SFC features, that wouldn't have taken place in an engine designed from the start for peripheral intake and side exhaust. Some engines, specially with direct injection systems, meet the problem of fuel droplets blocking access of the fuel spray to air, but with specially arranged deflectors, I remember one of these, (Pat DE2732562 by J M Ganzenmuller Sanchez), or with the incoming air duct tilted in a not paralel angle to the main chamber axis, with the aim of having the air or the air-fuel mix turning and spinning and swirling at desired speed and turbulence inside the working chamber, may in theory be an approach for some difficulties. There are some recent comments on the issue of combustion chamber shape and thermal losses, maintaining that is was not so bad as expected, look at the Ingersoll-Rand 44 liters chamber displacement gas fueled engines, that had a lower fuel use than reciprocating counterparts. Curtiss-Wright has shown that rotors can be widened (SAE Paper 790621, Charles Jones), so reaching a more square combustion chamber shape; the problem remains in seal efficacy at low rpm, that was addressed by several by changes in seals (Spanish patent 0418430 by Automobiles A CitroŽn).

(SAE Papers 730117, M K Eberle & E D Klomp; 730118 ,H F Prasse et al.) Another paper: 870447, J F Mannisto & R Bazaz covers rotor structural analysis. Very nice forum, very nice people! Thanks, Salut +

(1) Billy Joel (2) Diana Ross |

Edited by - urquiola on Jan 01 2013 3:48:50 PM |

|

|

|

Aaron Cake

Administrator

Canada

6718 Posts |

Posted - Jun 07 2010 : 7:03:58 PM Posted - Jun 07 2010 : 7:03:58 PM

|

I would suspect that peripheral intake and side exhaust ports would act the same way as a peripheral exhaust and side intake. It may actually be a little worse. With side exhaust ports large enough to flow enough gas (like the Renesis), there may be more overlap then with a peripheral port exhaust and side intakes. I'm just having a hard time rotating it all in my head to get a clear idea of what happens.

Mazda went with peripheral exhaust and side intake ports on all their production rotarys because they found it as an acceptable compromise until the Renesis came out. Actually, in the later years, the bit of overlap caused was not a big deal. They eliminated EGR as a result of it.

Wider rotors have been tried, but even Mazda is going back to thinner rotors with the new 16X rotary (which they say will run on gasoline, hydrogen, diesel and E85). Remember, the wider you go with the rotors, the lazier the engine is and the harder it is to make apex seals that won't flex.

This is just my personal opinion, but chasing piston like characteristics and fuel economy in a rotary just seems backwards. Build a rotary like a rotary should be built; to emphasize it's natural powerband. |

|

|

Topic Topic  |

|

|

|